humidity control sheet to prevent condensation

Prevents condensation for a long period of time without using electric power, realizing maintenance-free equipment inspection

Prevents condensation for a long period of time without using electric power, realizing maintenance-free equipment inspection

Effective solution against moisture/dew related problems

for electronic cabinets/enclosures.

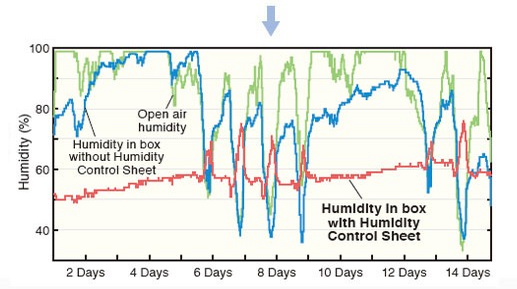

The Humidity level in a box with Humidity control sheet will be maintained in a fixed range.

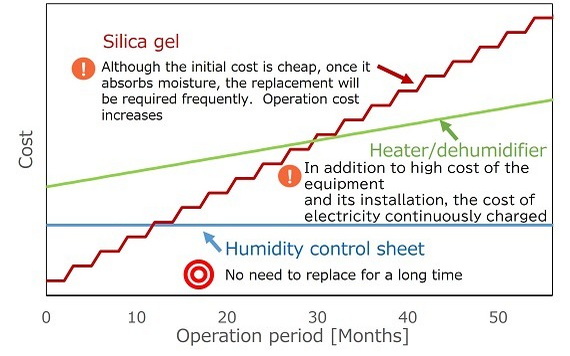

Desiccator like silica-gel works fine, but periodical replacement is a must.

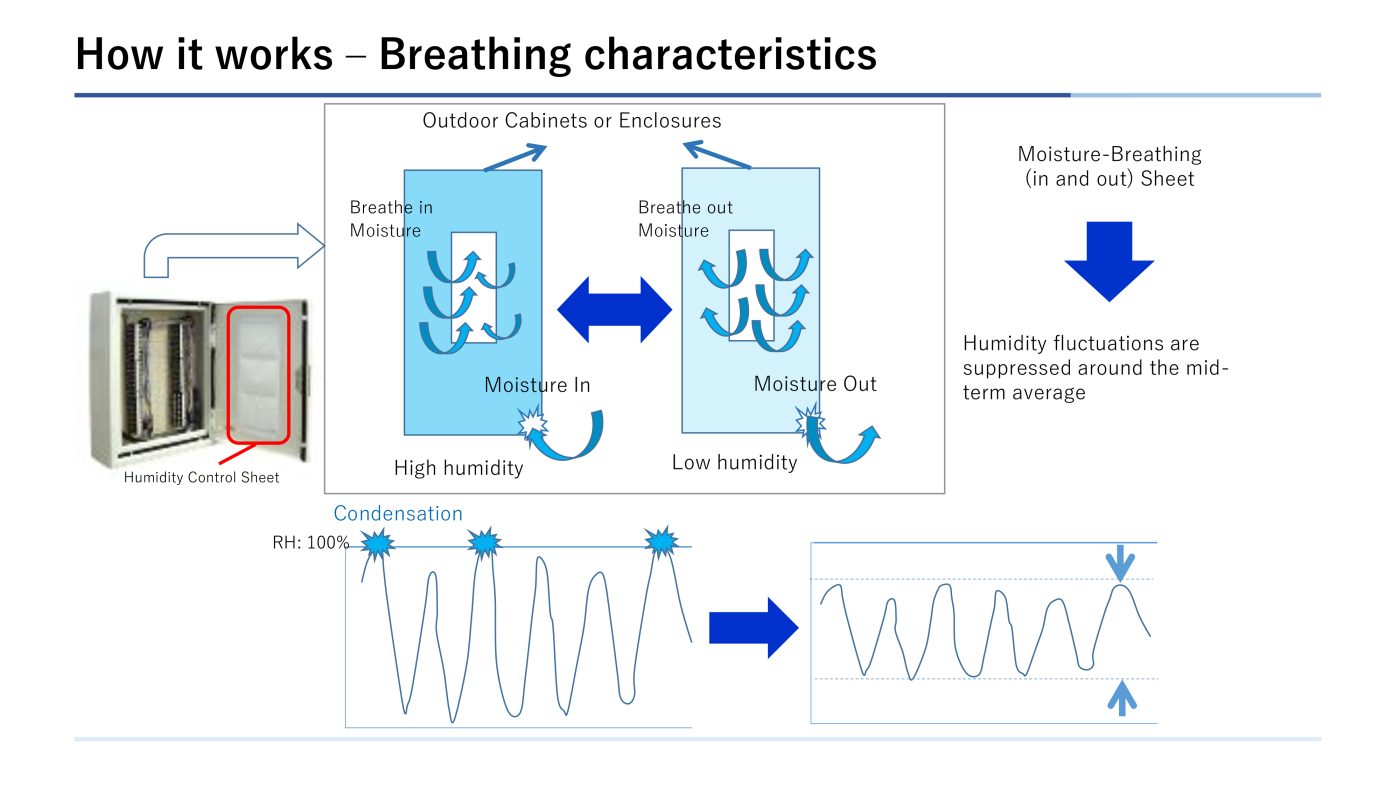

However, Humidity control sheet breath in and out moisture speedy. Which does not require frequent replacement, and helps to reduce maintenance time and labor cost significantly.

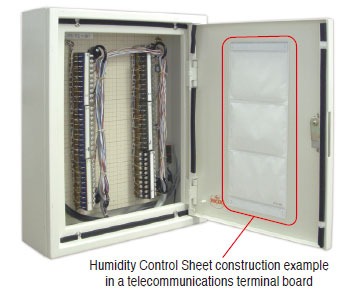

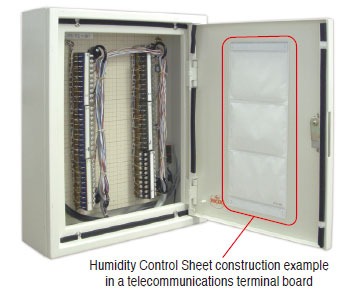

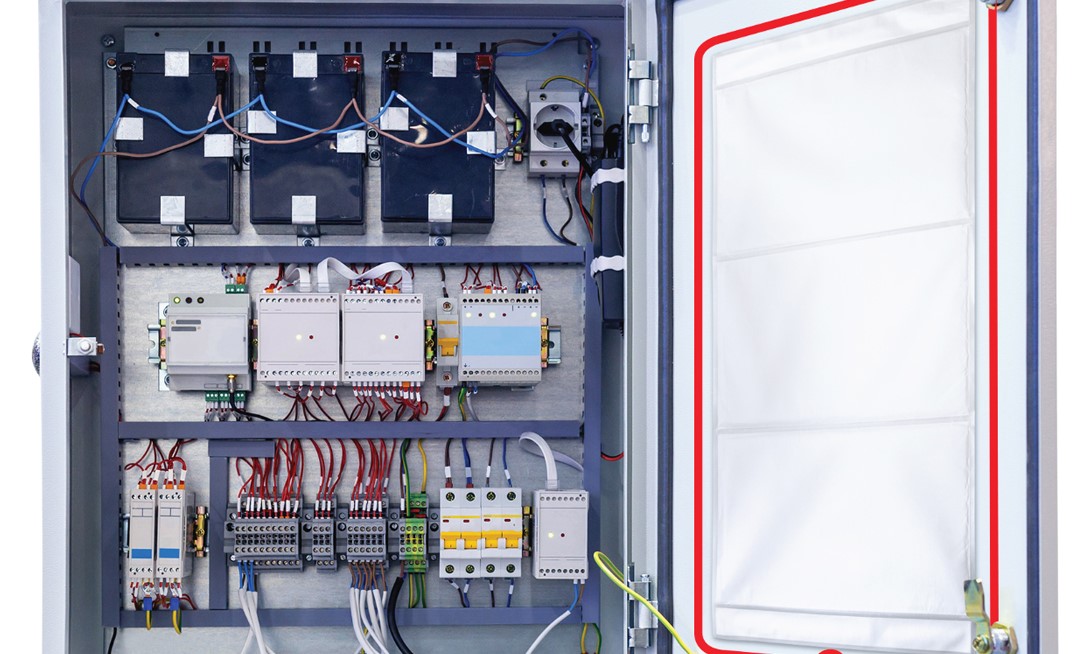

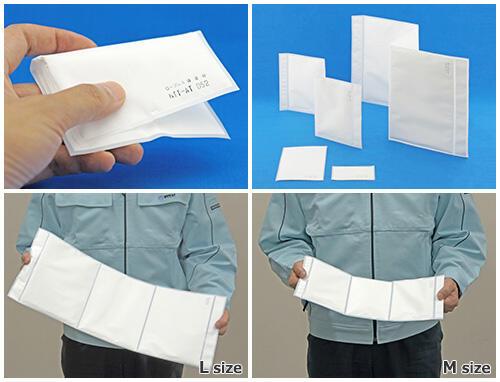

It can be attached easily in placed with limited spaces or even on curved surfaces.

NTT-AT can consult with each customer and advise suitable sheet size which fits the enclosure capacity

NTT-AT’s Humidity Control Sheet reduces increase in humidity inside the box and keeps comfortable environment for electric equipment.

Red line shows the Humidity in box with the Humidity control sheet.

Blue line shows the Humidity in box without the Humidity control sheet.

Green line shows the Open air humidity.

The box without Humidity control sheet shows the same humidity curve as the open air humidity.

Volume capacity of box used for testing:

13.9 liter

(5mm dia. vent hole at the bottom)

Humidity control sheet size: Post card size on the lid

Location: Hachioji Tokyo

Test period: 2 weeks

No frequent replacement will be needed like silica gel,result in reduction of the operation cost

No electricity will be needed. Installation cost is minimized

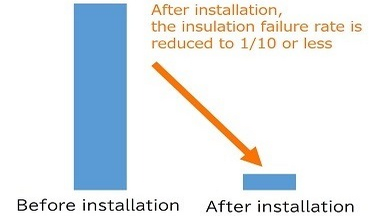

Reduce the insulation failure rate caused by dew condensation

* Effects will vary depending on the structure of the equipment to be installed and the environmental conditions.

It absorbs moisture quickly when the humidity rises, just like breathing, and releases moisture quickly when the humidity drops, suppressing fluctuations in humidity and preventing condensation. The anti-condensation sheet “Humidity Control Sheet” is a product that complies with the RoHS Directive.

In our outdoor tests, the humidity inside the box without the anti-condensation sheet “Humidity Control Sheet” (blue) changes according to the outside air humidity (green), while the inside of the box with the anti-condensation sheet “Humidity Control Sheet” Humidity (red) always maintains a certain range of humidity.

Humidity Control Sheet wicks away moisture without the need for high temperatures or sun drying to regenerate its wicking ability. Therefore, it responds to daily humidity fluctuations. Performance is maintained for a long period by repeatedly performing moisture absorption and desorption. In addition, since it is an ecological product that does not require electricity and does not require maintenance after installation, it reduces management effort and costs.

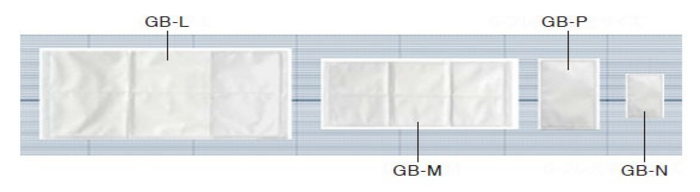

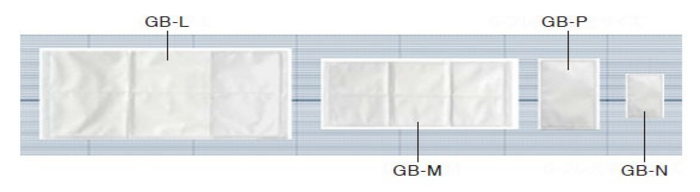

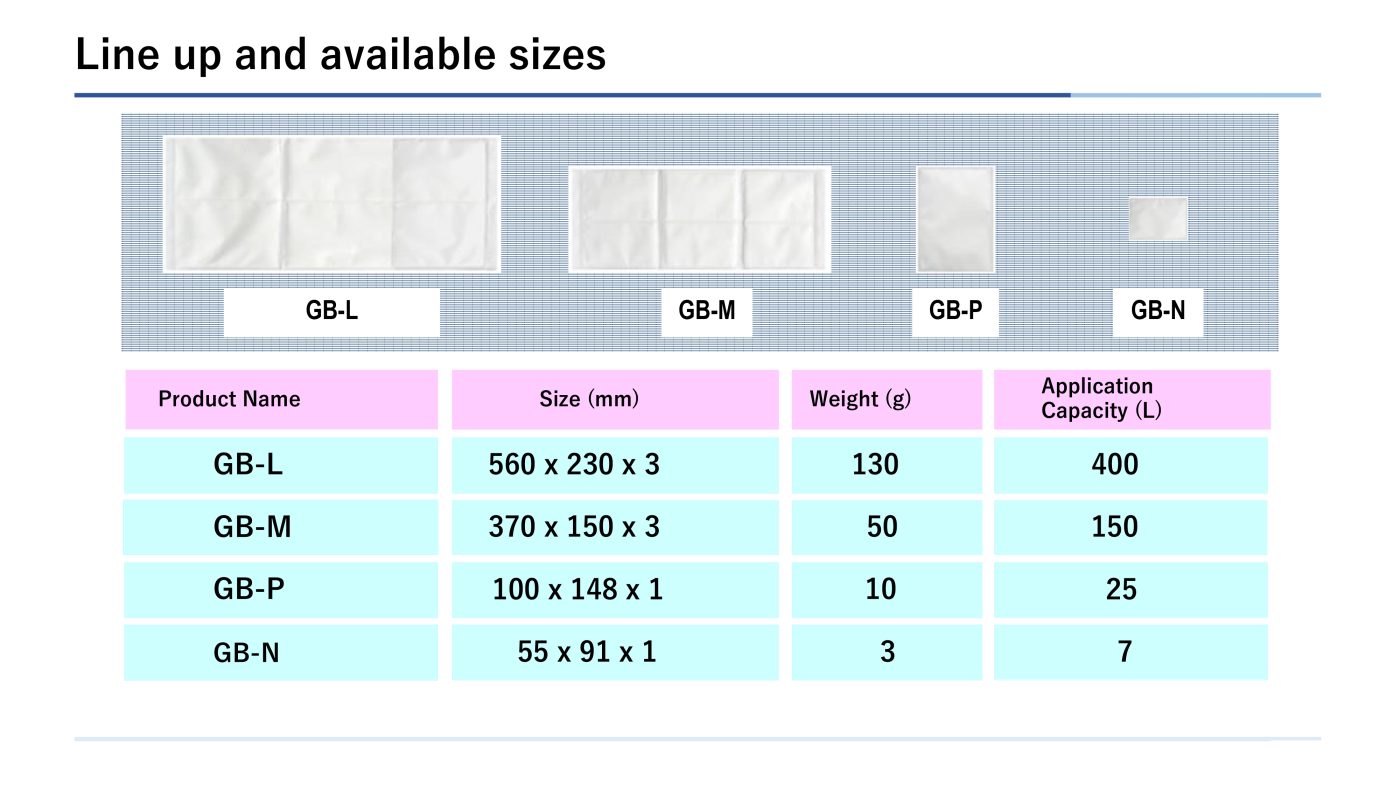

The anti-condensation sheet “Humidity Control Sheet” does not require electricity and is thin and light, so it can be easily installed in small spaces or on curved surfaces. We offer 4 different sizes, from business card size to small and large, according to the volume of the box to be constructed.

The anti-condensation sheet “Humidity Control Sheet” does not require electricity and is thin and light, so it can be easily installed in small spaces or on curved surfaces. We offer 4 different sizes, from business card size to small and large, according to the volume of the box to be constructed.

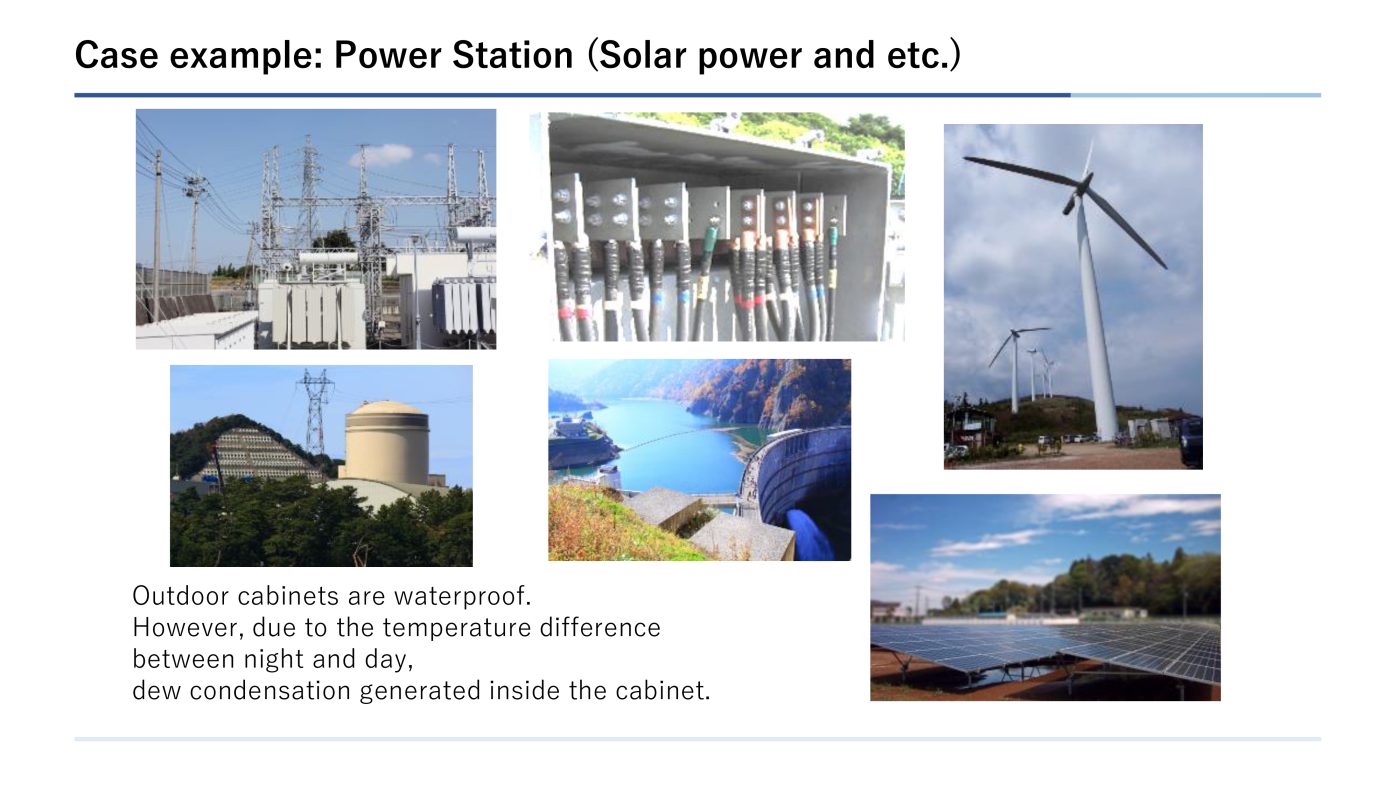

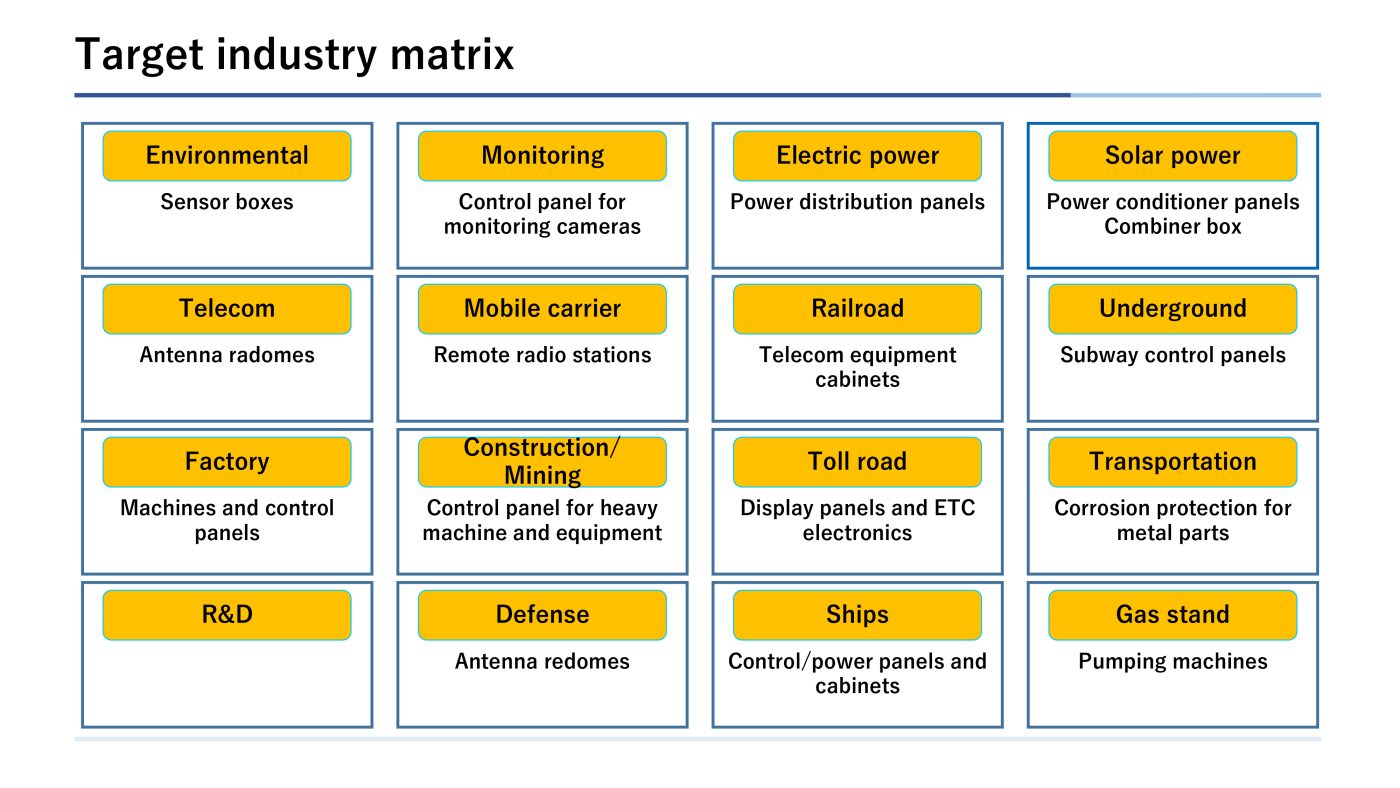

Due to its excellent humidity control ability, it has been widely adopted for its effectiveness in reducing equipment failures and maintenance costs. At the time of introduction, it is possible to realize more effective installation by first conducting an evaluation test..

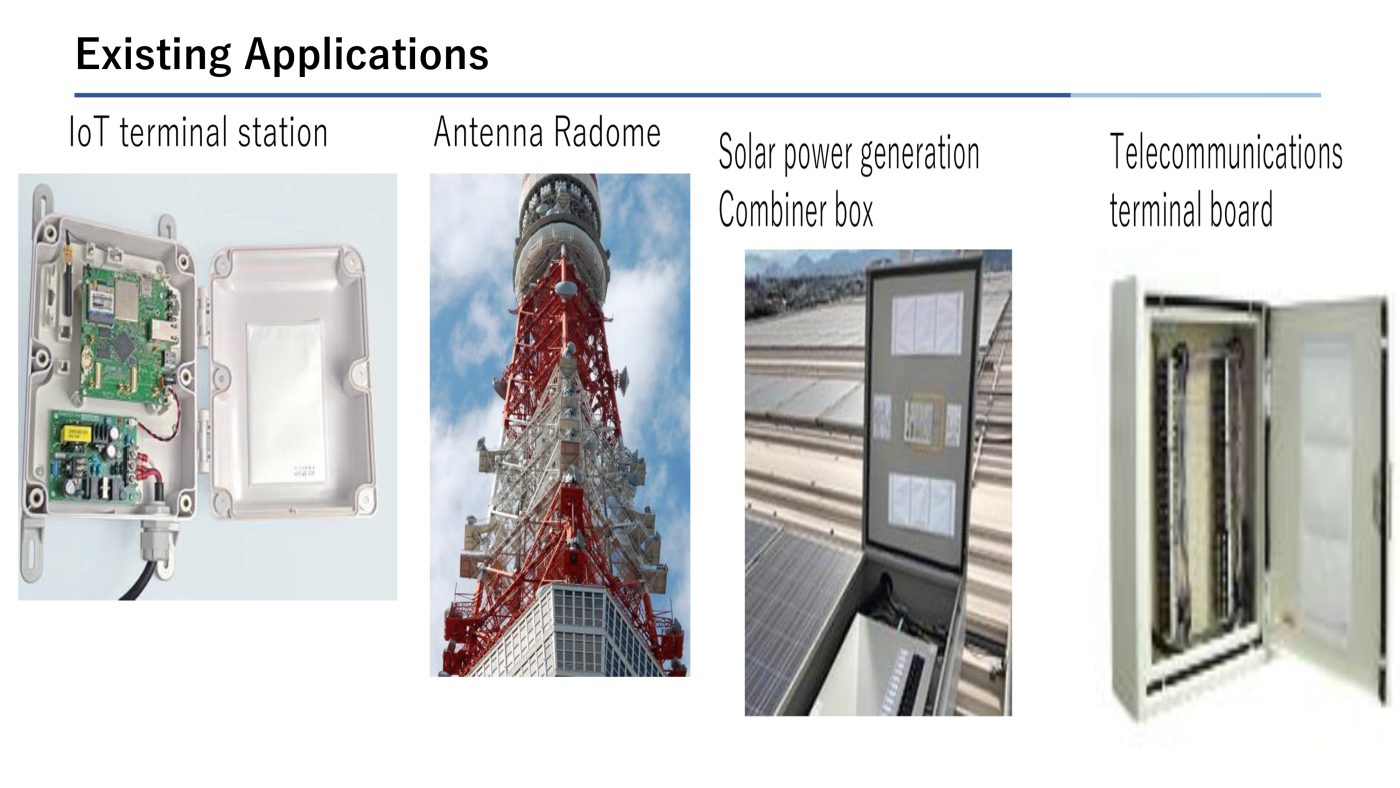

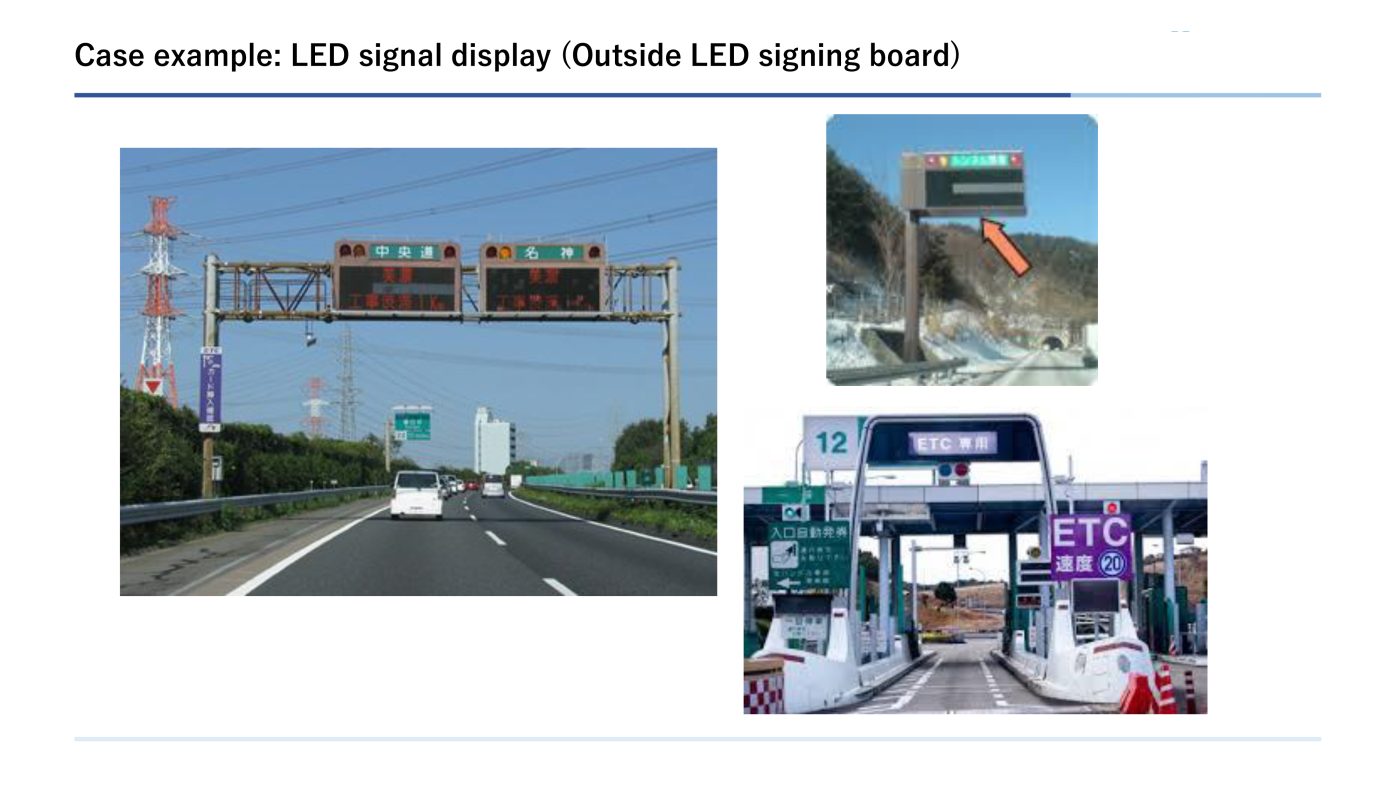

Introduced as a countermeasure against failures due to condensation that occurs in electrical equipment and equipment, and as a countermeasure against poor contact of terminals.

Introduced to prevent lowering of insulation resistance due to high humidity and condensation

Introduced to prevent short circuits in electrical equipment and substrates due to condensation